Supply chains are the backbone of global commerce, but they’re also incredibly complex systems that require constant optimization. Today’s supply chain managers face mounting pressure to reduce costs, improve efficiency, and respond faster to disruptions. Enter generative AI in supply chain management, a technology that’s reshaping how companies forecast demand, manage inventory, and respond to unexpected challenges.

According to recent industry data, the generative AI in the supply chain market is expected to reach around $27.4 billion by 2034, growing at a remarkable rate of 45.62% annually. More impressively, early adopters have experienced a 15% reduction in logistics costs and a remarkable 35% decrease in inventory levels, alongside a 65% improvement in service levels.

These numbers aren’t just statistics; they represent real operational improvements that can make or break competitive advantage. This article explores how generative AI is transforming supply chain operations, from predictive planning to risk mitigation, and what it means for businesses ready to embrace this technology.

What is Generative AI?

Generative AI represents a new class of artificial intelligence that goes beyond traditional predictive models. Unlike conventional AI that simply analyzes data and makes predictions, generative AI can create new content, scenarios, and solutions based on patterns it learns from existing information.

In the context of supply chains, this means AI systems that can generate demand forecasts, create optimization strategies, simulate thousands of delivery scenarios, and even produce actionable recommendations for complex logistics problems. These systems use advanced machine learning frameworks including generative adversarial networks and variational autoencoders to model data distributions and generate new insights.

The key difference lies in creativity and adaptability. Traditional AI might tell you what happened or what’s likely to happen. Generative AI can show you what could happen under different conditions, helping supply chain professionals explore possibilities they might never have considered. It’s like having a tireless analyst who can instantly create detailed scenarios for any situation you throw at it. With the global AI in supply chain market expected to reach $192.51 billion by 2034, this technology is rapidly becoming essential for competitive operations.

Why Generative AI Matters in Supply Chain

Supply chains today face more volatility than ever. From pandemic disruptions to geopolitical tensions, companies need tools that don’t just react but anticipate and adapt. Here’s why generative AI is becoming essential:

Enhanced Demand Forecasting

Traditional forecasting often relies on historical patterns and simple trend analysis. Demand forecasting using AI takes this further by analyzing hundreds of variables simultaneously, including weather patterns, social media trends, economic indicators, and seasonal behaviors. The result is forecasts that adapt in real time to changing conditions, helping companies avoid the twin problems of stockouts and excess inventory.

Optimized Inventory Management

Inventory management has always been a balancing act between having enough stock to meet demand and not tying up too much capital. Generative AI helps find that sweet spot by continuously analyzing demand signals, supplier performance, and storage costs. It can even simulate different inventory strategies and recommend the optimal approach for each product and location.

Faster Supply Chain Planning

Speed matters in modern supply chains. Projects that once took months can now be completed in weeks thanks to generative AI’s ability to process massive datasets and generate planning scenarios instantly. This acceleration means companies can respond faster to market changes and competitive pressures.

Improved Risk Management

Every supply chain faces risks from supplier failures to transportation disruptions. Generative AI excels at identifying potential problems before they occur by analyzing patterns across multiple data sources. It can generate early warning alerts and suggest mitigation strategies, helping companies maintain operations even during disruptions.

Cost Reduction and Efficiency

At the end of the day, supply chain improvements need to impact the bottom line. By optimizing routes, reducing waste, improving forecast accuracy, and streamlining operations, generative AI directly contributes to cost savings and operational efficiency across the entire supply chain network.

Generative AI in Supply Chain: Use Cases and Examples

Real-world applications of generative AI are transforming how companies manage their supply chains. Here are the most impactful use cases:

Predictive Inventory and Demand Planning

Generative AI analyzes historical sales data, market trends, promotional calendars, and external factors to create highly accurate demand forecasts. By doing so, companies can improve inventory management and achieve retail supply chain visibility at granular levels, accounting for regional differences, seasonal patterns, and emerging trends that traditional models might miss.

Production Optimization and Predictive Maintenance

Manufacturing equipment generates massive amounts of data. Generative AI uses this information to predict when machines are likely to fail, allowing maintenance teams to act before problems occur. This reduces unexpected downtime and keeps production lines running smoothly while extending equipment lifespan.

Route and Logistics Optimization

Transportation costs represent a significant portion of supply chain expenses. Generative AI can analyze millions of possible delivery routes, considering factors like traffic patterns, fuel costs, delivery windows, and vehicle capacity. The result is optimized routing that saves time, reduces fuel consumption, and improves delivery reliability.

Supplier and Procurement Management

Managing supplier relationships involves tracking performance, negotiating contracts, and assessing risks. Generative AI can analyze supplier data to identify the most reliable partners, predict potential supply disruptions, and even assist in contract negotiations by analyzing historical terms and market conditions.

Scenario Planning and Risk Mitigation

One of generative AI’s most powerful capabilities is creating realistic simulations of potential future scenarios. Supply chain managers can test how their networks would respond to various disruptions, from natural disasters to supplier bankruptcies, and develop contingency plans before problems arise.

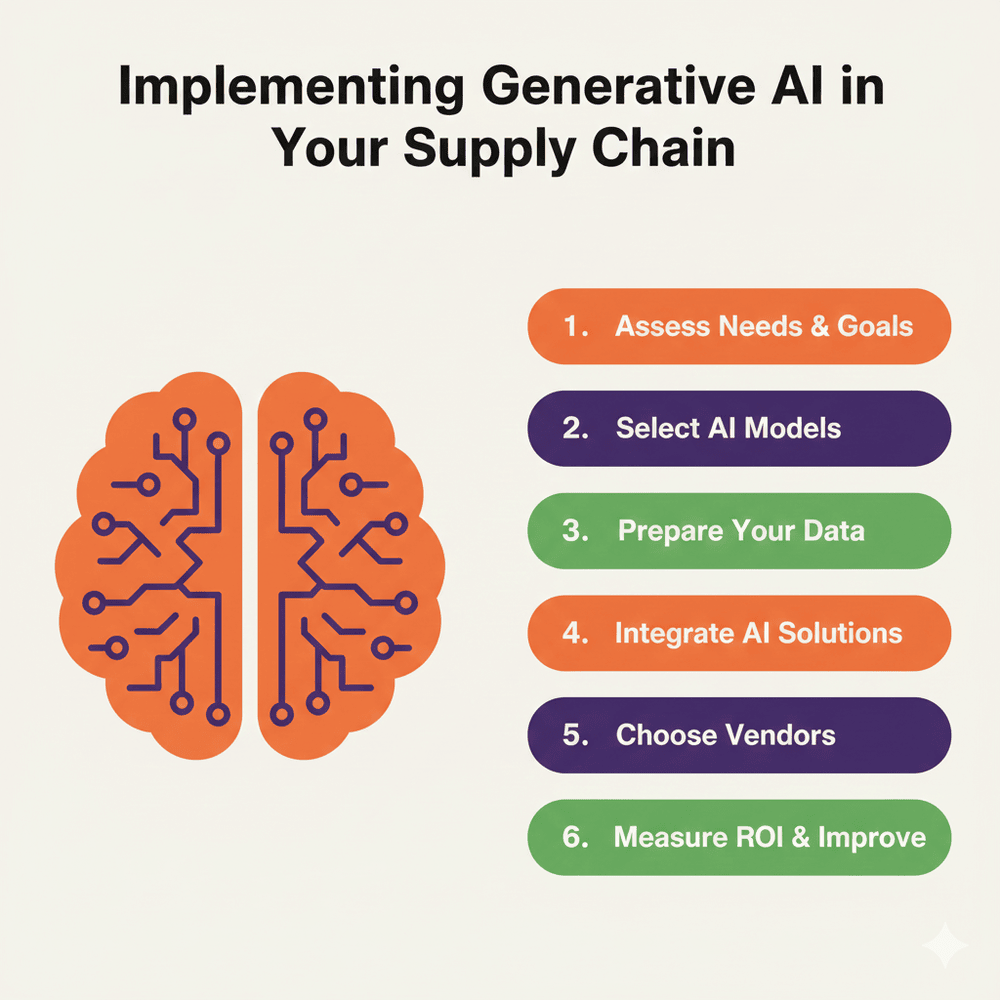

How to Implement Generative AI in Your Supply Chain

Successfully implementing generative AI requires careful planning and execution. Here’s a practical roadmap:

Assess Needs and Goals

Start by identifying your biggest supply chain challenges. Are you struggling with forecast accuracy? Do you have excess inventory? Are transportation costs eating into margins? Clear goals will guide your full-scale generative AI implementation and help measure success.

Choose AI Models

Not all AI models are created equal. Different supply chain problems require different approaches. Work with experts to select models that match your specific use cases, whether that’s demand forecasting, route optimization, or supplier risk assessment.

Prepare Data

Generative AI is only as good as the data it learns from. You’ll need to collect, clean, and organize data from across your supply chain. This includes sales history, supplier information, transportation records, and external data sources like weather and economic indicators. Taking the time to make your data AI-ready ensures that your models deliver accurate insights and reliable outputs.

Integrate AI solutions

Your AI tools need to work with existing systems like enterprise resource planning platforms, warehouse management systems, and transportation management software. Using AI powered enterprise search, your teams can quickly access the right data and insights across these systems, ensuring data flows smoothly and AI-driven recommendations can be acted upon quickly.

Select AI Vendors

Choosing the right technology partner is critical. Look for vendors with proven experience in supply chain applications, strong customer support, and solutions that can scale as your needs grow. Ask for case studies and references from companies similar to yours.

Measure ROI and Improve

Track key performance indicators to measure the impact of your AI implementation. Are forecasts more accurate? Have inventory levels improved? Are transportation costs declining? Use these metrics to continuously refine your approach and demonstrate value to stakeholders.

From assessing needs to choosing the right AI vendors, Folio3 ensures your generative AI deployment delivers real-world results.

Key Challenges of Generative AI in Supply Chains

While the benefits are clear, implementing generative AI isn’t without obstacles:

Data Quality Issues

Generative AI models require large volumes of high-quality data to function effectively. Many companies struggle with incomplete records, inconsistent formats, and data silos across different systems. Strong practices in big data engineering and management are essential to consolidate, clean, and structure this data. Without them, poor data quality leads to unreliable AI outputs and undermines confidence in the technology.

Integration Complexity

Most supply chains rely on multiple legacy systems that weren’t designed to work together. Implementing supply chain data integration alongside generative AI can be technically challenging and expensive, requiring significant IT resources and expertise.

Ethics and AI Bias

AI models can perpetuate biases present in their training data, leading to unfair outcomes in supplier selection, hiring decisions, or resource allocation. Companies need to carefully monitor their AI systems for bias and ensure decisions align with ethical standards.

Cost and Resource Constraints

Implementing generative AI requires investment in technology, talent, and infrastructure. Smaller companies may struggle to justify these costs, particularly when returns on investment aren’t immediately apparent or when competing priorities demand resources.

Proven Practices for Generative AI in Supply Chains

Learning from early adopters can help avoid common pitfalls:

Start with High-Quality Data

Before implementing any AI solution, invest time in cleaning and organizing your data. Establish clear data governance policies and ensure information flows consistently across your organization. Quality inputs lead to quality outputs. According to research from EY, AI adoption in sustainability tracking and measurement is as high as 62%, demonstrating the broad application of AI across supply chain functions.

Integrate AI Gradually

Don’t try to transform your entire supply chain overnight. Start with a focused pilot project in one area where you can demonstrate quick wins. Learn from this experience before expanding to other parts of your operation.

Align AI with Business Goals

Technology should serve business objectives, not the other way around. Ensure your AI initiatives directly support strategic goals like cost reduction, service improvement, or risk mitigation. This alignment helps maintain stakeholder support and demonstrates clear value.

Cross-Functional Collaboration

Supply chains touch every part of an organization. Successful AI implementation requires collaboration between IT, operations, procurement, logistics, and executive leadership. Break down silos and encourage teams to work together toward common goals.

Continuously Monitor and Update Models

The supply chain environment changes constantly. AI models that worked well last year may be less effective today. Regularly review performance metrics, retrain models with new data, and adjust parameters to maintain accuracy and relevance.

GenAI vs Traditional AI in Supply Chain: A Side by Side Comparison

| Feature | Traditional AI | Generative AI |

| Primary Function | Analyzes historical data and makes predictions based on patterns | Creates new scenarios, simulations, and solutions based on learned patterns |

| Use Cases | Demand forecasting, anomaly detection, classification | Scenario planning, content generation, optimization strategy creation |

| Data Requirements | Requires labeled historical data | Can work with both structured and unstructured data |

| Adaptability | Fixed models that require retraining for new scenarios | Can generate novel solutions for unprecedented situations |

| Output Type | Predictions, classifications, recommendations | New data, scenarios, strategies, content |

| Learning Approach | Supervised learning, pattern recognition | Generative models, unsupervised learning |

| Response to Change | Needs retraining when conditions change significantly | Can adapt and generate solutions for new situations |

| Complexity | Relatively straightforward implementation | More complex architecture and training requirements |

| Best For | Routine predictions and optimization | Creative problem-solving and scenario exploration |

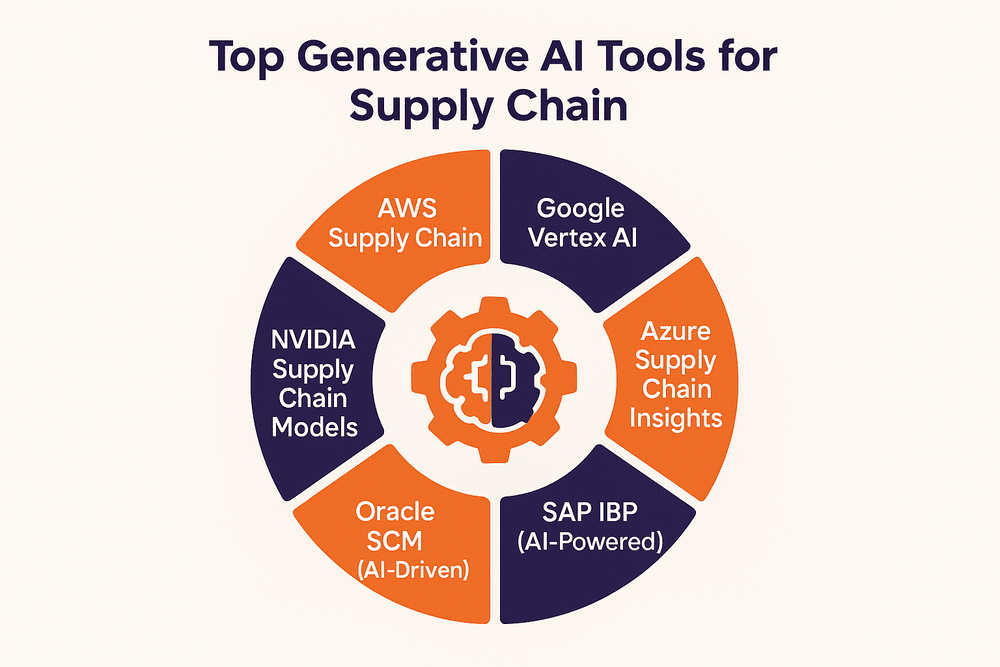

Top Tools and Platforms for Generative AI in Supply Chain

Several leading technology providers offer generative AI solutions specifically designed for supply chain applications:

AWS Supply Chain

Amazon’s supply chain solution leverages its vast logistics expertise to provide demand planning, inventory management, and supply chain visibility. The platform uses machine learning to generate accurate forecasts and identify potential disruptions before they impact operations.

Google Vertex AI

Google’s enterprise AI platform offers tools for building and deploying machine learning models at scale. Supply chain teams can use Vertex AI to create custom generative models for specific use cases, leverage pre-built solutions for common supply chain problems, and apply generative AI for data analysis to uncover insights that improve forecasting, inventory management, and operational efficiency.

Azure Supply Chain Insights

Microsoft’s cloud-based platform combines AI, IoT, and analytics to provide end-to-end supply chain visibility. The solution uses generative AI to simulate scenarios, optimize operations, and predict potential disruptions across complex global networks.

SAP IBP with AI

SAP’s Integrated Business Planning solution incorporates AI and machine learning for demand sensing, inventory optimization, and supply chain planning. The platform integrates seamlessly with other SAP systems, making it a natural choice for companies already using SAP software.

Oracle SCM with AI

Oracle’s supply chain management suite includes AI-powered features for planning, procurement, logistics, and manufacturing. The platform uses generative AI to optimize supply chain decisions and provide actionable insights to supply chain professionals.

NVIDIA Supply Chain Models

NVIDIA provides GPU-accelerated AI frameworks and pre-trained models specifically designed for supply chain applications. These tools enable companies to build and deploy generative AI solutions with the computational power needed for complex supply chain optimization.

Technologies Behind Generative AI in Supply Chains

Understanding the underlying technologies helps appreciate what makes generative AI so powerful:

Machine Learning Models

At the core are sophisticated machine learning algorithms including neural networks, deep learning models, and reinforcement learning systems. These models process vast amounts of data to identify patterns and generate insights that humans might miss.

Generative AI Frameworks

Specific architectures like generative adversarial networks, transformer models, and variational autoencoders enable AI systems to create new content and scenarios. These frameworks are what give generative AI its creative problem-solving capabilities.

IoT and ERP Integration

Generative AI doesn’t work in isolation. It relies on real-time data from Internet of Things sensors throughout the supply chain and integrates with enterprise resource planning systems for seamless ERP data integration, allowing operational data to be accessed and actionable insights to be executed efficiently.

Data Preparation Requirements

Before AI can generate useful insights, data must be collected, cleaned, normalized, and structured appropriately. Using data extraction AI can help automate the process of gathering and standardizing data from multiple sources, including handling missing values, removing duplicates, and ensuring consistency across the entire supply chain network.

Case Study: Generative AI Success Stories in Supply Chains

Real-world examples demonstrate the transformative impact of generative AI:

Walmart: Optimized Replenishment System

Walmart has developed a system called Trend-to-Product, an AI-driven, multi-agent engine that tracks trends using social media and search data, generates product concepts, and feeds them directly into prototyping and sourcing processes. The retail giant uses generative AI across its global supply chain to forecast demand, optimize inventory placement, and respond to disruptions in real time. The company uses AI-powered systems in distribution centers to analyze and predict automation alerts, providing guidance on next steps and often automating resolution.

Maersk: GenAI Customer Service

The global shipping leader implemented generative AI to transform customer service and supply chain communications. By implementing AI in customer analytics, Maersk can process vast amounts of logistics data to provide customers with more accurate delivery estimates and proactively address potential delays before they impact shipments.

Amazon: Purchase Order Automation

Amazon shared investments in AI applications that solve logistics challenges including Wellspring, a generative AI mapping technology, and an AI-powered demand forecasting model powering Amazon’s supply chain. The company’s Supply Chain Optimization Technology serves as the central nervous system, managing millions of sellers while making countless predictions and decisions daily.

GXO: Automated Inventory Counting

The logistics company deployed generative AI and computer vision systems to automate inventory counting in warehouses. This eliminated the time-consuming manual process of physical inventory checks while improving accuracy and freeing staff to focus on higher-value tasks.

Leading enterprises like Walmart, Maersk, and Amazon are already transforming their supply chains with generative AI. Folio3 can help you achieve the same level of efficiency and innovation.

Emerging Generative AI Trends in Supply Chain

The future of generative AI in supply chains looks even more transformative:

Autonomous AI Supply Chains

AI including machine learning and generative AI are the top digital supply chain investment priorities according to a survey by Gartner conducted with 419 supply chain leaders. We’re moving toward fully autonomous supply chains where AI systems make routine decisions without human intervention, from reordering inventory to rerouting shipments around disruptions.

Real-Time Scenario Simulations

Advanced generative AI will enable instant creation and testing of countless supply chain scenarios. Managers will be able to explore “what if” questions in seconds, comparing different strategies and understanding potential outcomes before making decisions.

Hyper-Personalized Supply Management

As consumer expectations for personalization grow, supply chains will need to deliver customized products and services at scale. Generative AI will enable mass customization by optimizing production, inventory, and delivery for individual customer preferences.

AI as Decision Partner

Rather than simply providing recommendations, generative AI will become a true decision-making partner. These systems will understand business context, explain their reasoning, and collaborate with human managers to solve complex supply chain challenges.

FAQs

What is generative AI in the supply chain?

Generative AI in the supply chain uses advanced AI to create strategies, simulate scenarios, and generate actionable insights for optimization, beyond simple data analysis.

How does generative AI improve supply chain efficiency?

It enhances efficiency by improving demand forecasts, optimizing inventory, streamlining routes, predicting equipment issues, and testing strategies, reducing costs and delays.

What are the risks of using AI in the supply chain?

Risks include poor data quality, system integration challenges, AI bias, cybersecurity threats, and over-reliance on technology without human oversight.

Which industries benefit most from AI in supply chains?

Industries like retail, manufacturing, automotive, healthcare, food & beverage, and consumer goods gain the most from AI due to complex logistics and variable demand.

How is generative AI different from traditional AI in supply chains?

Traditional AI analyzes historical data for predictions. Generative AI creates new scenarios and solutions, supporting scenario planning and problem-solving for novel situations.

Can generative AI predict supply chain disruptions?

Yes, it can detect potential disruptions by analyzing weather, supplier performance, market trends, and geopolitical events, while recommending mitigation strategies.

What are the key use cases of generative AI in logistics and procurement?

Use cases include supplier negotiations, risk assessment, contract compliance, demand forecasting, route optimization, scenario planning, and predictive maintenance.

How does generative AI help in demand forecasting?

It analyzes sales, seasonal trends, promotions, market data, and external factors to generate multiple forecast scenarios and provide granular, real-time predictions.

What tools and platforms support generative AI for supply chains?

Leading platforms include AWS Supply Chain, Google Vertex AI, Microsoft Azure Supply Chain Insights, SAP IBP, Oracle SCM, and specialized AI solutions for logistics and demand planning.

How much does it cost to implement generative AI in supply chain operations?

Costs vary by size and scope, from tens of thousands for small pilots to millions for enterprise-wide deployment, covering software, integration, training, and maintenance.

Can small and medium-sized businesses benefit from AI in supply chains?

Yes, cloud-based AI solutions allow SMBs to adopt targeted applications like demand forecasting or inventory optimization without large upfront costs.

How does generative AI enhance supply chain decision-making?

It accelerates data analysis, compares multiple scenarios, alerts to potential issues, explains recommendations, and continuously learns to improve decisions.

What data is required to train generative AI for supply chain optimization?

Key data includes sales history, inventory, supplier performance, logistics, production schedules, order fulfillment, external factors, and customer behavior.

Conclusion

Generative AI is not just another technology trend. It represents a fundamental shift in how supply chains operate, plan, and respond to challenges. From demand forecasting to risk mitigation, from inventory optimization to route planning, generative AI delivers measurable results that improve efficiency, reduce costs, and enhance service levels.

Folio3 provides complete data solutions for supply chains, helping organizations manage and make sense of the data that powers these AI-driven improvements. Our expertise in data integration, engineering, and analytics ensures that data is collected, cleaned, and transformed into practical insights.

By enabling real-time visibility, accurate forecasting, and informed decision-making through cloud platforms like Snowflake, Databricks, and AWS, Folio3 helps organizations use data to improve efficiency and gain a competitive edge.

The companies embracing these technologies today are building competitive advantages that will serve them for years to come. While implementation requires investment and careful planning, the potential returns make it difficult to ignore.

As supply chains grow more complex and customer expectations continue rising, generative AI will move from being a nice-to-have to an essential tool for survival. The question isn’t whether to adopt generative AI in your supply chain, but how quickly you can get started and where you’ll see the biggest impact first.