Effective inventory forecasting is a cornerstone of modern supply chain and business operations. By accurately predicting future product demand, companies can optimize stock levels, reduce carrying costs, and enhance customer satisfaction. This process involves analyzing historical sales data, market trends, and seasonal fluctuations to anticipate inventory needs.

Implementing robust inventory forecasting methods and models enables businesses to align their inventory planning with actual market demand, minimizing the risks of overstocking or stockouts. Incorporating advanced technologies, such as artificial intelligence and machine learning, further refines these forecasts, leading to more precise inventory management and improved operational efficiency.

What is Inventory Forecasting? – Definition of Inventory Forecasting

Inventory forecasting, also known as demand planning, is the practice of predicting future inventory requirements by analyzing historical sales data, market trends, and upcoming events. This strategic approach enables businesses to maintain optimal stock levels, ensuring product availability aligns with customer demand while minimizing excess inventory costs.

By accurately forecasting inventory needs, companies can enhance operational efficiency, reduce storage expenses, and improve customer satisfaction. For instance, in November 2024, U.S. business inventories experienced a modest increase of 0.1%, reflecting efforts to balance supply with anticipated demand.

Effective inventory forecasting involves several key components:

- Lead Time Demand: Calculating the expected product demand during the supplier lead time.

- Sales Trends Analysis: Evaluating historical sales patterns to identify seasonal fluctuations and growth trajectories.

- Reorder Point Determination: Establishing the inventory level at which new stock orders should be placed to prevent stockouts.

- Safety Stock Calculation: Maintaining a buffer stock to mitigate uncertainties in demand and supply.

Why Inventory Forecasting is Crucial for Businesses?

Accurate inventory forecasting is vital for businesses aiming to balance supply with customer demand, thereby optimizing operational efficiency and profitability. By predicting future inventory requirements through analyzing historical sales data, market trends, and upcoming events, companies can maintain optimal stock levels, reducing the risks of overstocking or stockouts.

This strategic approach not only minimizes holding costs but also enhances cash flow, freeing up resources for other critical business activities. Moreover, precise demand forecasting in inventory management enables businesses to streamline their supply chain operations, improve customer satisfaction by ensuring product availability, and make informed decisions regarding production planning and resource allocation.

Incorporating advanced technologies, such as artificial intelligence, machine learning, and data analytics solutions, into inventory forecasting models further refines accuracy, allowing companies to adapt swiftly to market fluctuations and consumer behavior changes. This technological integration is becoming increasingly prevalent, with retailers using AI to enhance demand planning and reduce inventory distortion costs, which were estimated at $1.77 trillion globally in 2023.

Types of Inventory Forecasting

Understanding the various types of inventory forecasting is essential for businesses aiming to maintain optimal stock levels and meet customer demand efficiently. Each forecasting method offers unique insights, and selecting the appropriate approach depends on specific business needs and market conditions.

Demand Forecasting

This method involves predicting future sales by analyzing historical sales data, market trends, and consumer behavior. By understanding past demand patterns, businesses can anticipate future needs and adjust inventory accordingly. For example, retail demand forecasting often involves analyzing previous holiday season sales to forecast inventory requirements for the upcoming season.

Supply Forecasting

This approach estimates the availability of materials and evaluates supply chain factors that could impact inventory levels. By assessing supplier reliability, lead times, and potential disruptions, companies can plan for contingencies and ensure a steady supply of products. For instance, a manufacturer might evaluate the lead times of various suppliers to determine the most reliable source for raw materials.

Qualitative Forecasting

Based on expert opinions, market research, and emerging trends, qualitative forecasting is particularly useful when historical data is limited or when launching new products. This method relies on insights from industry experts, customer surveys, and focus groups to gauge future demand. For example, a tech company introducing a new gadget might consult industry analysts to predict market reception and demand.

Quantitative Forecasting

Utilizing statistical and mathematical models, quantitative forecasting analyzes numerical data to predict future inventory needs. Techniques such as time series analysis, regression models, and machine learning algorithms fall under this category. For instance, a business might use forecasting inventory based on sales patterns through time series analysis to identify seasonal trends and adjust inventory levels accordingly.

Trend-Based Forecasting

This method focuses on identifying patterns and trends over time, such as seasonal fluctuations or market-driven changes in demand. By recognizing these trends, businesses can proactively adjust their inventory to align with anticipated changes. For example, a clothing retailer may increase stock of swimwear in anticipation of summer demand.

Causal Forecasting

Causal forecasting examines the relationship between external factors and demand changes. By linking variables such as economic indicators, marketing campaigns, or weather conditions to sales data, businesses can predict how these factors will influence demand. For instance, a company might analyze how a recent advertising campaign has impacted product sales and adjust future inventory orders based on the findings.

Benefits of Inventory Forecasting

Implementing effective inventory forecasting offers significant advantages that directly impact a company’s profitability, operational efficiency, and customer satisfaction. By using accurate demand forecasting in inventory management, businesses can optimize stock levels and improve supply chain resilience.

Cost Reduction

One of the most immediate benefits of inventory forecasting is cost reduction. By accurately predicting future demand, businesses can minimize storage costs, avoid over-purchasing, and reduce product wastage. Overstocking ties up capital and increases holding costs, while understocking leads to lost sales opportunities.

Improved Customer Satisfaction

Ensuring product availability is key to retaining customers and driving repeat business. Inventory planning and forecasting help businesses maintain optimal stock levels, reducing the likelihood of stockouts and backorders.

Better Cash Flow Management

Accurate inventory forecasting directly impacts a company’s financial health. By aligning inventory investments with actual demand, businesses can optimize their working capital and free up cash for other critical operations.

Efficient Supply Chain Operations

Effective inventory forecasting enhances collaboration between suppliers, manufacturers, and distributors. When businesses have a clear understanding of how to forecast inventory levels, they can communicate better with suppliers, ensuring timely restocking and reducing supply chain disruptions.

Reduced Uncertainty

Data-driven forecasting minimizes guesswork, allowing businesses to make proactive decisions based on real-time insights. Using inventory forecasting formulas and models, companies can anticipate demand fluctuations, plan for seasonal changes, and mitigate risks associated with sudden market shifts. This predictive approach is particularly valuable in industries with volatile demand, such as retail and e-commerce, where forecasting accuracy can make or break profitability.

Best Practices for Effective Inventory Forecasting

To maximize the accuracy and efficiency of inventory forecasting, businesses must adopt data-driven strategies and use modern technology. Below are key best practices that ensure precise demand forecasting in inventory management, leading to better decision-making and operational efficiency.

Use Real-Time Data

Real-time inventory tracking enhances forecasting accuracy by providing up-to-date stock levels and demand fluctuations. By integrating IoT-enabled inventory management tools, companies can dynamically adjust forecasts based on real-time demand signals. Leveraging these tools is considered one of the best ways to forecast inventory, helping businesses maintain optimal stock levels and reduce stockouts or overstock situations.

Integrate Forecasting with Supply Chain Management

Effective inventory planning and forecasting require alignment with procurement, warehousing, and logistics. Companies that synchronize inventory forecasting models with supply chain processes see a 15% improvement in order fulfillment rates. This integration ensures that supply chain bottlenecks, lead times, and supplier performance are considered in demand planning.

Use Automation and AI

Advanced forecasting tools, powered by machine learning, significantly improve inventory forecasting accuracy. AI-driven models analyze historical sales data, market trends, and external factors to provide precise predictions. Businesses using AI-based inventory forecasting formulas reduce forecasting errors by up to 50%, according to McKinsey.

Monitor and Adjust Forecasts Regularly

Market conditions and consumer behavior are constantly evolving. A static inventory forecasting strategy may lead to overstocking or shortages. Regularly reviewing and updating forecasts based on the latest demand trends allows businesses to stay agile.

Collaborate Across Departments

Successful inventory forecasting involves input from multiple departments, including sales, finance, and operations. Cross-functional collaboration ensures that financial constraints, marketing promotions, and sales forecasts align with inventory levels. Research from McKinsey & Company highlights that companies excelling in customer experience, which often involves cross-departmental collaboration, achieve 1.7 times higher customer retention and 1.9 times the return on spend.

Segment Products Based on Demand Volatility

Not all inventory items follow the same demand pattern. Segmenting products based on demand volatility such as high-demand, seasonal, and slow-moving categories improves forecast precision. For example, a fashion retailer can forecast seasonal apparel differently from staple items, reducing markdowns and optimizing turnover.

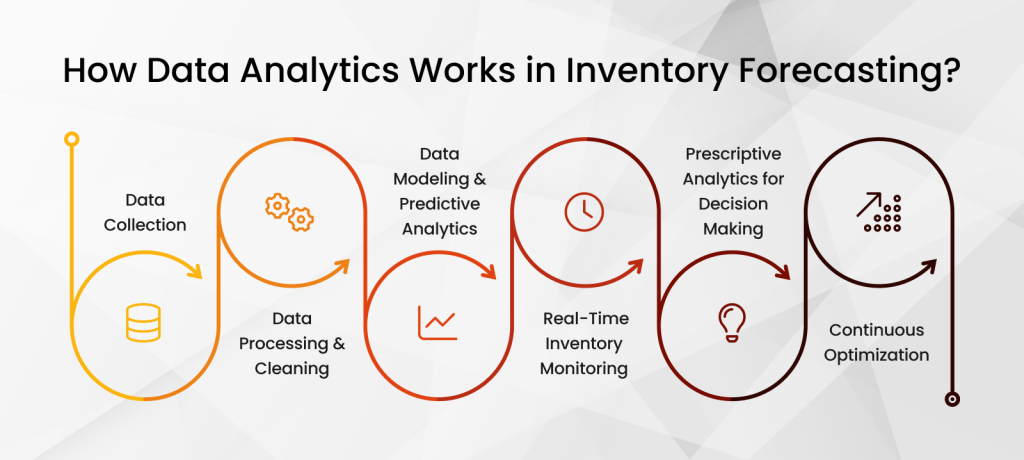

How Data Analytics Works in Inventory Forecasting?

Data analytics plays a pivotal role in improving inventory forecasting accuracy, helping businesses minimize waste, optimize stock levels, and enhance overall supply chain efficiency.

By using predictive analytics and automation, companies can develop precise demand forecasting models that align with real-time market trends.

Here’s a breakdown of how data analytics enhances inventory planning and forecasting:

1. Data Collection

The foundation of inventory forecasting lies in collecting accurate and comprehensive data. By leveraging data analytics services, businesses gather data from multiple sources, including:

- Sales history – Identifying purchasing patterns and peak demand periods.

- Supplier performance – Tracking lead times and fulfillment accuracy.

- Market trends – Understanding seasonal fluctuations and external factors.

- IoT & RFID sensors – Providing real-time stock updates.

2. Data Processing & Cleaning

Raw data often contains inconsistencies, missing values, or errors that can distort forecasting accuracy. Cleaning and structuring this data ensures more reliable predictions. Key steps include:

- Data normalization – Standardizing values for consistency.

- Outlier detection – Identifying and removing anomalies.

- Missing value treatment – Using imputation techniques to fill gaps.

3. Data Modeling & Predictive Analytics

Once the data is cleaned, businesses apply statistical and machine learning models to forecast future inventory needs. Some commonly used inventory forecasting models include:

- Time series analysis – Identifying seasonal trends using historical data.

- Regression models – Linking demand to factors like pricing, promotions, and economic conditions.

- AI & machine learning algorithms – Using neural networks and decision trees to detect hidden demand patterns.

These techniques form the backbone of demand forecasting and inventory management, enabling businesses to align stock levels with predicted customer demand efficiently.

4. Real-Time Inventory Monitoring

By integrating IoT and cloud-based inventory management systems, businesses can track inventory in real time. This allows for:

- Automated restocking alerts – Preventing stockouts and overstocking.

- Demand fluctuations tracking – Adjusting forecasts dynamically.

- Supplier coordination – Optimizing replenishment schedules.

5. Prescriptive Analytics for Decision Making

Beyond predicting demand, prescriptive analytics recommends actionable strategies for inventory planning and forecasting. These insights help businesses:

- Adjust pricing and promotions based on expected demand.

- Optimize warehouse space utilization.

- Streamline procurement and supplier negotiations.

6. Continuous Optimization

Inventory forecasting is an ongoing process that requires constant refinement. Businesses must:

- Continuously evaluate forecast accuracy.

- Integrate new data sources for better predictions.

- Adapt models to changing market conditions.

Inventory Forecasting Techniques for Different Business Models

Inventory forecasting is not a one-size-fits-all approach. Different business models—whether retail, manufacturing, or wholesale—require specialized inventory forecasting methods to optimize stock levels and prevent overstocking or stockouts. Below are tailored forecasting techniques for each sector:

1. Retail and E-commerce

Retail and e-commerce businesses face dynamic customer demand, making accurate inventory forecasting essential to prevent lost sales and excess stock.

- Seasonal Demand Forecasting – Retailers must analyze historical sales data to anticipate seasonal trends. For example, holiday shopping spikes require predictive models to ensure optimal inventory levels.

- Handling Promotions and Discount Campaigns – Promotions can cause sudden demand fluctuations. Businesses use regression analysis and machine learning models to forecast the impact of price reductions on sales.

2. Manufacturing

Manufacturers rely on precise inventory forecasting to manage raw material procurement and ensure production continuity.

- Material Requirement Planning (MRP) – This approach forecasts the required materials based on production schedules, ensuring just-in-time (JIT) inventory availability.

- Supplier Lead Time Considerations – Supplier performance directly impacts inventory availability. Manufacturers use predictive analytics to estimate lead times, preventing production delays.

3. Wholesale and Distribution

Wholesalers and distributors must manage bulk inventory movements while mitigating demand variability.

- Bulk Inventory Replenishment – Demand-driven replenishment models help wholesalers predict when and how much stock to reorder, reducing holding costs while maintaining supply reliability.

- Demand Variance Handling – Wholesalers deal with fluctuating customer demand from retailers and other businesses. By using advanced forecasting techniques, such as machine learning and causal forecasting, they can dynamically adjust stock levels.

FAQs

Why is inventory forecasting important for businesses?

It helps maintain optimal stock levels, reduce costs, prevent stockouts, and improve cash flow and customer satisfaction.

What data is needed for accurate inventory forecasting?

Businesses need historical sales data, supplier performance metrics, market trends, and real-time inventory tracking.

What are common challenges in inventory forecasting?

Challenges include demand fluctuations, supply chain disruptions, inaccurate data, and lack of advanced forecasting technology.

how can predictive analytics optimize inventory planning?

Predictive analytics uses historical data, demand trends, and market insights to forecast inventory needs accurately. It helps reduce stockouts, prevent overstocking, optimize reorder points, and improve supply chain efficiency. By leveraging machine learning and data-driven insights, businesses can make smarter inventory decisions, cut costs, and boost operational performance.

Final Words

Inventory forecasting is a game-changer for businesses looking to optimize stock management, reduce costs, and improve operational efficiency. Using data analytics, automation, and AI-driven models, companies can accurately predict demand, streamline supply chain operations, and stay ahead of market trends.

Whether in retail, manufacturing, or wholesale, implementing robust forecasting techniques ensures better decision-making and long-term profitability. For businesses looking to integrate AI-powered forecasting solutions, Folio3 provides cutting-edge inventory management tools that enhance accuracy, efficiency, and business growth.

Reach out today to learn how our solutions can transform your inventory forecasting strategy!